Central Pumps in Meghalaya

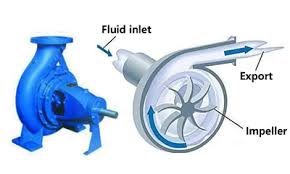

A centrifugal pump is a mechanical device designed to move fluids (liquids or slurries) by converting rotational kinetic energy into hydrodynamic energy. This energy transformation is achieved through a rotating impeller that imparts velocity to the fluid, directing it outward into a volute or diffuser, where the velocity is converted into pressure.

Centrifugal pumps are widely used across industries such as water treatment, chemical processing, oil & gas, food & beverage, and power generation because of their efficiency, simple design, and ability to handle large volumes of fluid.

Key Points in Description:

- Working Principle: Operates on the principle of centrifugal force. As the impeller rotates, it accelerates fluid outward from the centre (eye) to the periphery, creating flow and pressure.

- Main Components:

- Impeller (rotating part that imparts energy to the fluid)

- Casing/Volute (directs fluid flow and converts velocity into pressure)

- Shaft & Bearings (support rotation)

- Seal or stuffing box (prevents leakage along the shaft).

- Types: Classified based on impeller design (radial, axial, mixed flow), casing type (volute, diffuser), and suction arrangement (single or double).

- Applications: Water supply, irrigation, sewage handling, HVAC systems, chemical transfers, and boiler feed systems.