Filter Press in Bhopal

Different sizes & Models available, starting price is 38,000/-.

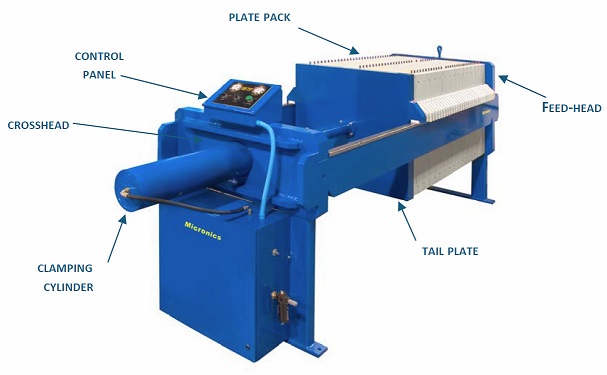

A Filter Press is a solid–liquid separation equipment used in laboratories, industries, and wastewater treatment plants. It works on the principle of pressure filtration, where slurry (a mixture of solids and liquids) is pumped into the press, and the liquid passes through filter cloths while solids are retained as a filter cake.

The device consists of a series of filter plates lined with filter cloths, arranged alternately with frames and held tightly together in a frame structure. When pressure is applied, the liquid portion (filtrate) flows out through the cloth into collection channels, and the solid residue builds up between the plates.

Dimensions:-

- UTFP-12x12 : 12" x 12" + 11 No. Plates

- UTFP-18x18 : 18" x 18" + 17 No. Plates

- UTFP-18x24 : 18" x 24" + 23 No. Plates

- UTFP-24x24 : 24" x 24" + 23 No. Plates

- UTFP-30x30 : 30" x 30" + 29 No. Plates

- UTFP-32x32 : 32" x 32" + 31 No. Plates

- UTFP-36x36 : 36" x 36" + 35 No. Plates

- UTFP-40x40 : 40" x 40" + 39 No. Plates

- UTFP-48x48 : 48" x 48" + 47 No. Plates

Key Features of a Filter Press

- Solid–Liquid Separation – Efficiently separates solids from liquids using pressure filtration.

- Filter Plates & Cloths – Equipped with filter plates lined with filter cloths to retain solid particles and allow filtrate to pass.

- Filter Cake Formation – Collects solid material (filter cake) between plates, which can be easily removed after filtration.

- Adjustable Pressure – Operates under hydraulic or mechanical pressure to achieve effective filtration.

- Material of Construction – Made from durable materials such as cast iron, stainless steel, or polypropylene, ensuring chemical resistance.

- Variety of Sizes & Capacities – Available in laboratory-scale units to large industrial machines for high-volume operations.

- Automation Options – Can be manual, semi-automatic, or fully automatic, depending on application needs.

- Reusability – Filter cloths are washable and reusable, reducing operational costs.

- High Filtration Efficiency – Produces clear filtrate with minimal solid content.

- Applications Versatility – Suitable for pharmaceuticals, food & beverages, mining, chemicals, dyes, and wastewater treatment.